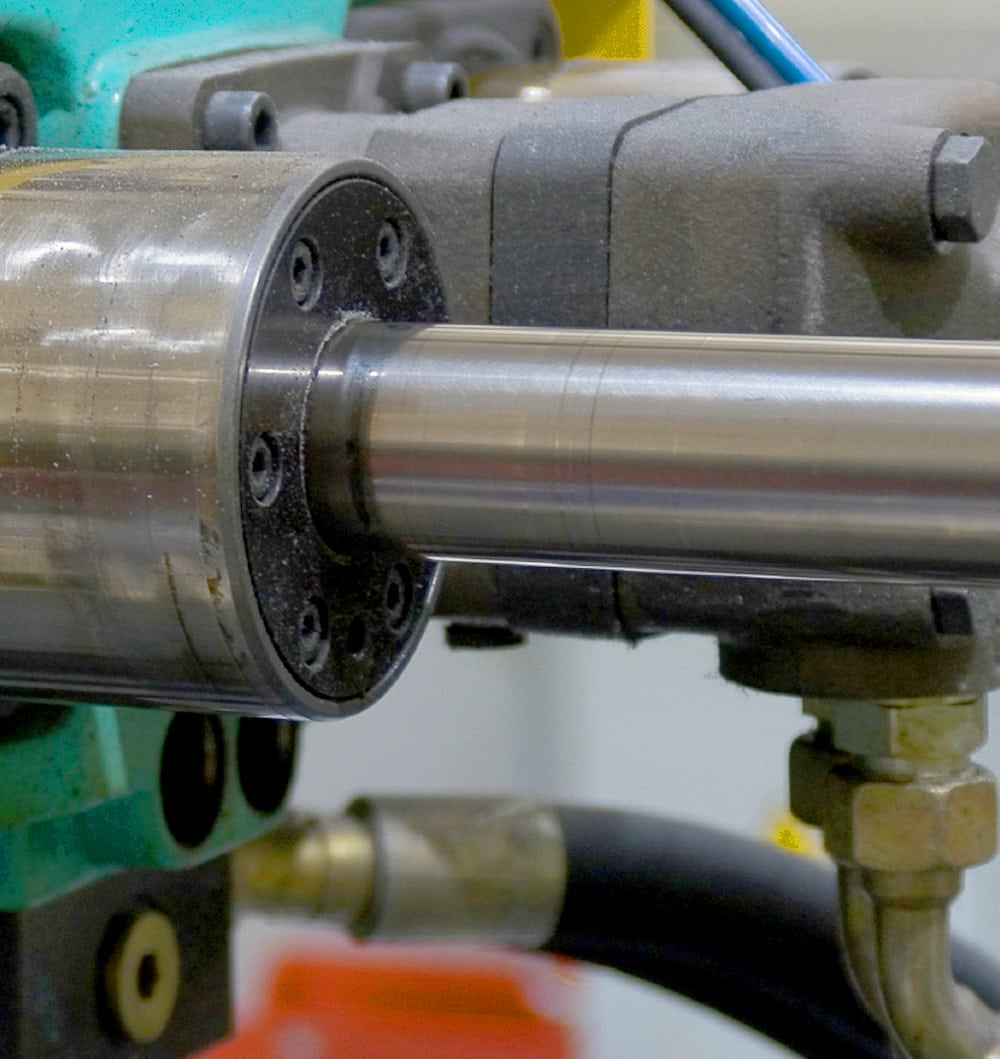

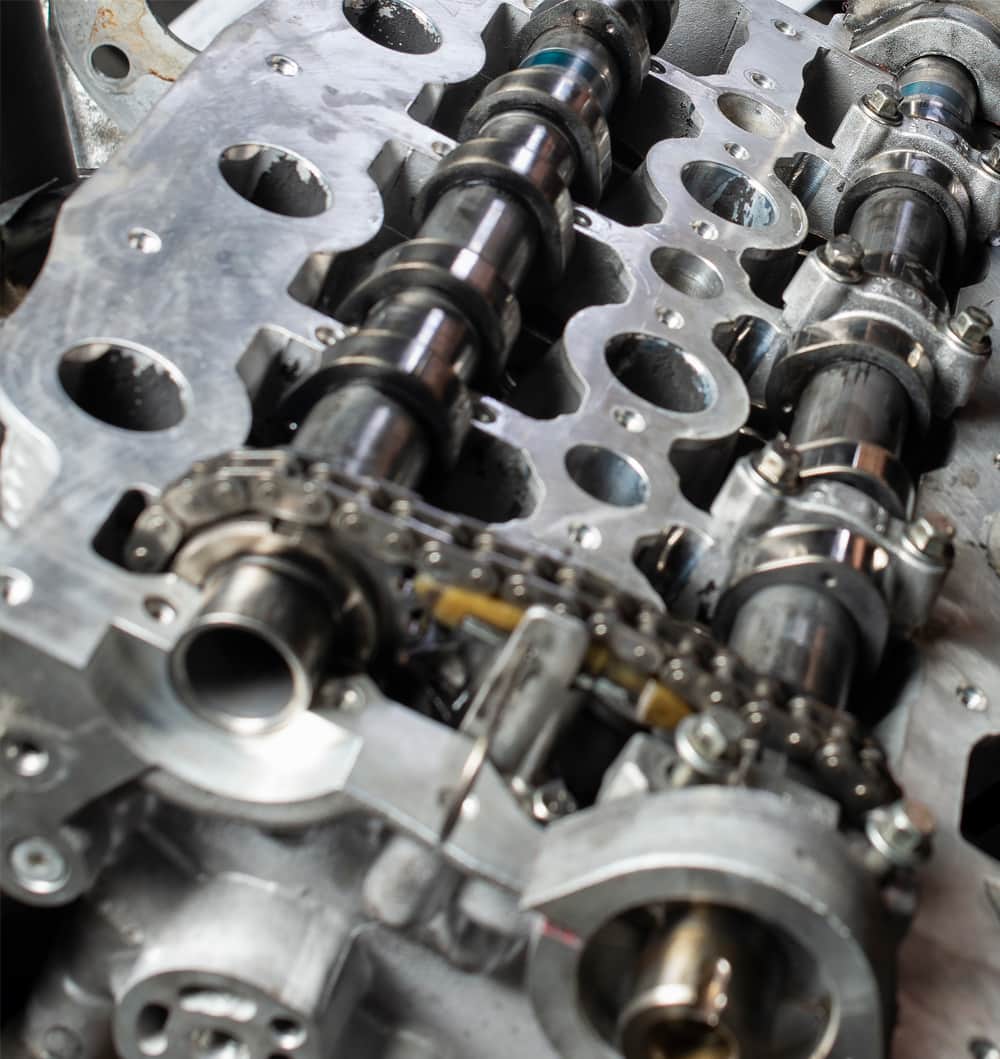

Investing in better-performing lubricants can make your plant more reliable by protecting your equipment and keeping it running longer and more efficiently.

Lubrication Engineers manufactures and distributes a comprehensive line of high-performance lubricants that far exceed conventional lubricants in a variety of industrial and automotive applications. By significantly reducing downtime and maintenance costs, LE lubricants are also cost-effective, returning the initial price of the lubricant many times over.

LE’s enhanced lubricants are made of highly refined or synthetic base oils as well as the following proprietary additives, which LE developed for exclusive use in its lubricants.

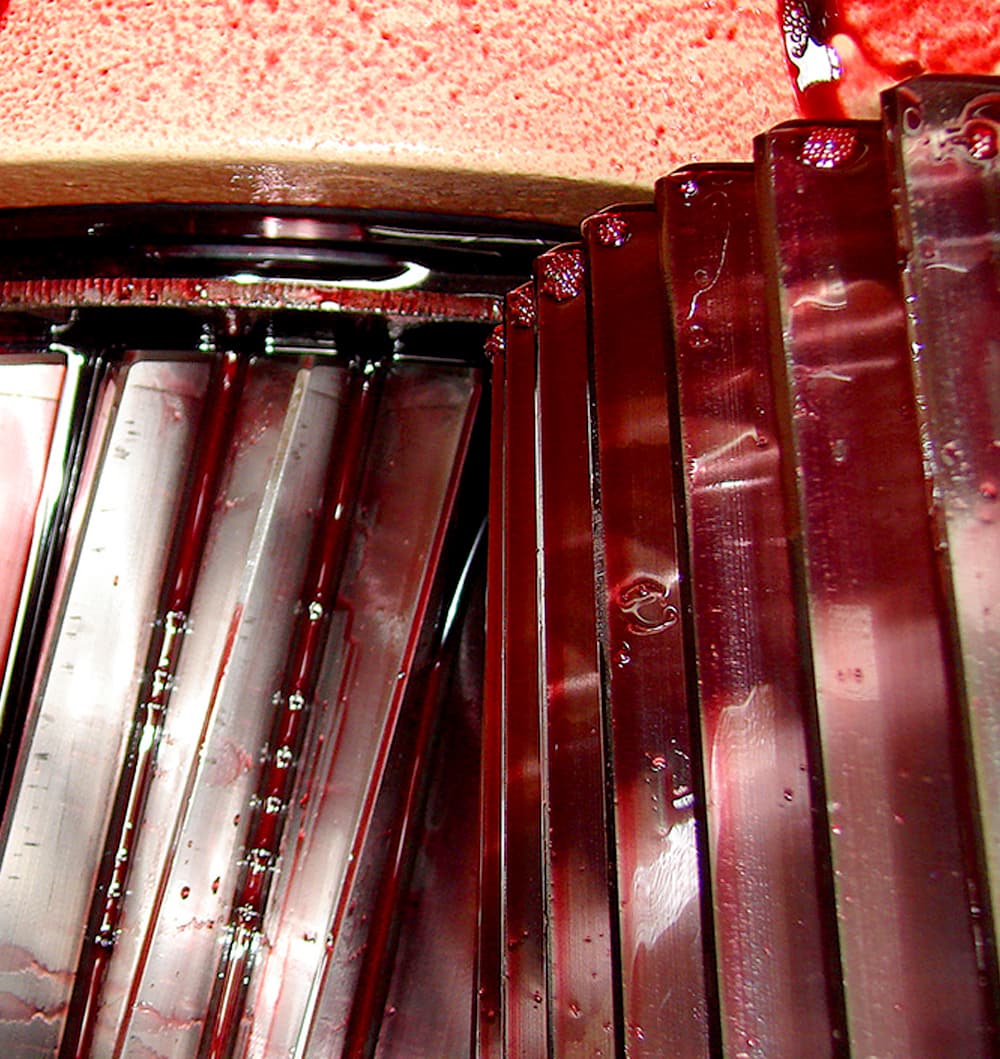

- Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances.

- Monolec® liquid wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing film strength without affecting clearances.

- Duolec® dual-acting additive imparts synergistic properties to lubricants, providing both wear-reducing and extreme pressure protection. It increases film strength and is temperature-activated to provide a protective layer.

- Quinplex® impact-resistant additive contributes to outstanding water resistance, tackiness, and mechanical stability, and helps to form a barrier against corrosion.

Not resting on its laurels, LE’s state-of-the-art technology center engages in full-time research and development, ensuring our customers that the most effective technology is available for incorporation into the LE product line.